High Shear Homogenizer Mixers

Tlhaloso e Khutšoanyane:

Li-Mixers tsa rona tsa High Shear Homogenizer li sebelisoa ho pholletsa le liindasteri tse ngata, ho kenyeletsoa liindasteri tsa meriana, lijo, litlolo, enke, likhomaretsi, lik'hemik'hale le lijalo. Motsoako ona o fana ka mekhoa e matla ea ho phalla ha radial le axial le ho kuta ho matla, e ka finyella lipakane tse fapaneng tsa ts'ebetso ho kenyeletsa homogenization, emulsification, phofo ea metsi le deagglomeration.

Video ho Youtube: https://youtube.com/shorts/bQhmySYmDZc

Lintlha tsa Sehlahisoa

Li-tag tsa Sehlahisoa

Lintlha

E etsa ts'ebetso ea ho fetisetsa mohato o le mong kapa ho feta ka mokhoa o atlehileng, ka potlako le ka mokhoa o lekanang (mokelikeli, o tiileng, oa khase) ho ea karolong e 'ngoe e sa lumellaneng e tsoelang pele (hangata e le metsi). Ka kakaretso, mohato o mong le o mong ha o lumellane le o mong. Ha matla a ka ntle a kenngoa, lisebelisoa tse peli li tsosolosoa ho ea homogeneous phase. Ka lebaka la lebelo le phahameng la tangential le hlahisoang ke ho potoloha ka lebelo le phahameng la rotor le matla a matla a kinetic a tlisoang ke phello ea mochini o phahameng oa maqhubu, thepa e tlas'a sekoala se matla sa mochini le sa hydraulic, extrusion ea centrifugal, likhohlano tsa mokelikeli, ho taboha le pherekano ka lekhalo le moqotetsane pakeng tsa stator le rotor, ho fella ka ho emisa mokelikeli (o tiileng / mokelikeli), emulsion (mokelikeli / mokelikeli) le foam (khase / mokelikeli). E le hore mekhahlelo e tiileng, e nang le mokelikeli le ea khase e ka qhalakantsoeng 'me ea emulsified ka mokhoa o ts'oanang le e ntle hang-hang tlas'a ketso e kopanetsoeng ea theknoloji e hōlileng e lumellanang le li-additives tse loketseng,' me joale lihlahisoa tse tsitsitseng tsa boleng bo phahameng li ka fumanoa ka ho palama libaesekele le ho khutlisa.

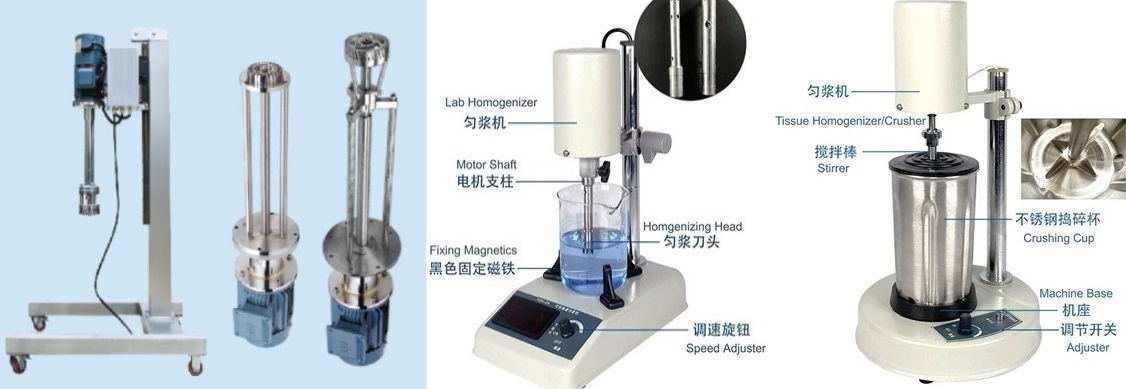

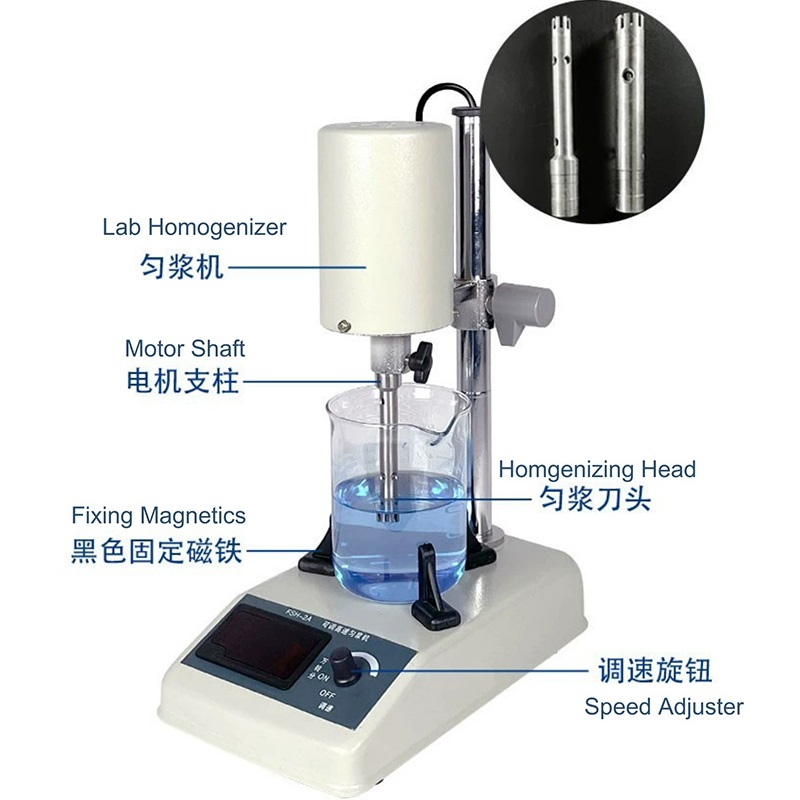

Likarolo tsa High Shear Dispersing Emulsifier

1. Bokhoni bo boholo ba ho sebetsa, bo loketseng tlhahiso e tsoelang pele ea liindasteri tsa inthanete;

2. Kabo ea boholo ba likaroloana tse moqotetsane le ho tšoana ho phahameng;

3. Ho boloka nako, ho sebetsa hantle haholo le ho boloka matla;

4. Lerata le tlaase le ts'ebetso e tsitsitseng;

5. Felisa phapang ea boleng pakeng tsa lihlopha;

6. Boema-kepe ba ho monya homogenizer bo ka monya ka ho toba karolo ea thepa e tala ka har'a rotor ebe e e khaola ka ntle ho 'mele oa pompo;

7. Ha ho na angle e shoeleng, 100% ea thepa e kuta ka ho qhalakanngoa;

8. Ka ts'ebetso ea ho tsamaisa sebaka se sekhuts'oane, se phahamiso e tlase;

9. E bonolo ho e sebelisa ebile e bonolo ho e hlokomela;

10. E ka hlokomela taolo e iketsang.

Lisebelisoa tsa High Shear Mixers

Li-mixer tse phahameng tsa ho kuta li ka bonoa ho tsoa liindastering tsohle tse hlokang hore metsoako e kopanngoe. Ka tlase ke ts'ebeliso ea li-mixer tse phahameng tsa ho kuta.

Tlhahiso ea Lijo

Ho na le mefuta e mengata e fapaneng ea li-mixer tse phahameng tsa ho kuta tlas'a sehlopha sena. Li-mixer tse phahameng tse sebelisoang indastering ea lijo li ka etsa li-emulsions, suspensions, powders le granules. Tšebeliso e tloaelehileng ke ho etsa li-sauces, lirosa le likuku. Bongata ba metsoako bo entsoe ka likaroloana tse tiileng, le lino tse sa tsitsang tse kang oli le metsi.

Lisebelisoa tse ling li thata haholo ho li lokisa tse kang ketchups, mayonnaise le hlama. Mekelikeli ena le li-semi-solids li na le thepa ea viscoelastic e hlokang matla a fokolang pele a theha phallo. Sena se hloka lihlooho tse kopanyang tsa rotor-stator.

Meriana le Litlolo

Joalo ka indastering ea lijo, meriana e sebetsana le mefuta e fapaneng ea metsoako. Li-mixer tse phahameng tsa ho kuta li sebelisoa ka lebaka la tsamaiso ea eona e koetsoeng e felisang ho kenella leha e le hofe ha litšila. Lihlahisoa tsohle tsa meriana tse kang matlapa, li-syrups, suspensions, litharollo tsa ente, mafura, li-gel le litlolo li feta ka har'a motsoako o phahameng oa ho kuta, kaofela ha tsona li na le viscosity le boholo bo sa tšoaneng.

Lipente le Liaparo

Lipente (latex) li tsejoa e le mokelikeli o seng oa Newtonian, thixotropic. Sena se etsa hore ho be thata ho sebetsa lipente. Penta e tšesaane ha e ntse e kuta, ebang ke ka ho sebetsa kapa ka ho qetela. Nako ea ho kopanya bakeng sa maro ana a laoloa ka hloko ho thibela ho kuta.

Tlhahiso ea li-Inks le Toner

Viscosity ea li-inks (printer) e fapane le lipente. Li-inks li nkoa e le rheopectic. Mekelikeli ea Rheopectic e teteana ha e ntse e kuta, e etsa hore nako ea ho kopanya e itšetlehe.

Petrochemicals

Lisebelisoa tse tlas'a sehlopha sena li kenyelletsa ho kopanya li-resin le solvents bakeng sa ho lahla kapa ho etsa ente, ho fetola ponahalo ea oli, ho hlahisa boka ba boka, tlhahiso ea asphalt, joalo-joalo.